Common PDR limitations in automotive repairs, such as dent complexity, vehicle panel variations, and technician skill levels, significantly impact repair outcomes. While Pre-Delivery Inspection (PDR) systems offer cutting-edge solutions for quality control, they struggle with subtle defects like miniscule cracks or faint dents. Human expertise remains crucial to supplement automated processes, particularly in complex vehicle designs and challenging manufacturing conditions. Analysis of PDR limitations case studies reveals recurring issues like inadequate training, inferior tools, and technique misapplication, affecting both aesthetic appeal and long-term structural integrity. Addressing these limitations is vital for improving customer satisfaction within the auto body restoration industry.

“Uncovering the hidden pitfalls of Pre-Delivery Inspection (PDR) systems is crucial for maintaining vehicle quality and customer satisfaction. This article explores real-world case studies highlighting common PDR challenges, from technological shortcomings to human errors. By delving into software compatibility issues, data security concerns, training deficiencies, and subjective inspections, we identify key limitations holding PDR back. Leveraging these insights, the article offers practical strategies for overcoming these obstacles, ensuring more efficient and reliable pre-delivery processes.”

- Uncovering Common PDR Challenges: A Case for Understanding

- – Exploring real-world scenarios where PDR (Pre-Delivery Inspection) systems faced limitations.

- – Identifying recurring issues and their impact on vehicle quality and customer satisfaction.

Uncovering Common PDR Challenges: A Case for Understanding

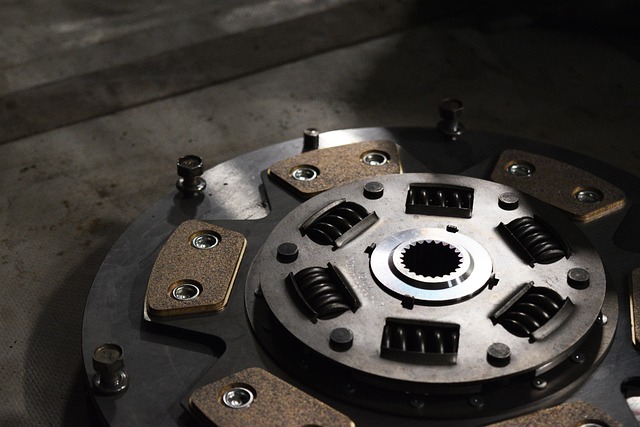

Uncovering common challenges associated with PDR (Paintless Dent Repair) is essential for anyone involved in the automotive industry, from collision repair shops to dedicated paintless dent repair specialists. By studying case studies and real-world examples, professionals can gain valuable insights into the potential limitations and pitfalls of this popular repair method. Many factors contribute to these challenges, including the complexity of dent sizes and shapes, vehicle panel variations, and the skill level of technicians.

For instance, a recent case study highlighted the difficulties faced by an automotive body shop when attempting PDR on a car with intricate body panels. The unique design presented technical obstacles, as certain dents proved challenging to reach and required specialized tools not commonly found in standard collision repair shops. Understanding these cases helps establish a more realistic approach to PDR, ensuring that expectations are set appropriately for both clients and technicians, ultimately leading to better outcomes and customer satisfaction.

– Exploring real-world scenarios where PDR (Pre-Delivery Inspection) systems faced limitations.

In the realm of automotive quality control, Pre-Delivery Inspection (PDR) systems are often hailed as a game-changer for car body shops and dealerships. However, exploring real-world scenarios reveals that these systems aren’t infallible. For instance, consider cases where PDR technology failed to detect subtle defects in new vehicles, such as miniscule cracks in auto glass repair or faint dents that weren’t captured by the system’s sensors. These limitations underscore the importance of human expertise in complementing automated processes.

Additionally, navigating complex vehicle designs and varying conditions can pose challenges for PDR systems. For example, certain car models with unique body panels or vehicles subjected to harsh manufacturing conditions might not yield consistent results. This is especially pertinent when discussing auto glass repair, where precision matters, and even the slightest oversight can lead to structural integrity issues. As a result, while PDR technology offers significant advantages, it’s crucial to recognize its constraints and ensure that human technicians remain integral to the quality control process, addressing any PDR limitations for comprehensive vehicle inspections in car body shops.

– Identifying recurring issues and their impact on vehicle quality and customer satisfaction.

By examining case studies on PDR (Paintless Dent Repair) limitations, we can uncover recurring issues that significantly impact vehicle quality and customer satisfaction in auto body restoration processes. Common problems include inadequate training among technicians, use of inferior tools, or misapplication of techniques, leading to visible imperfections after repairs. These issues not only detract from the overall aesthetic appeal but also raise concerns about long-term structural integrity.

Moreover, focusing on fender repair and body shop services, PDR limitations often reveal a disconnect between expected results and actual outcomes. Customers who invest in paintless dent repair expect flawless, invisible repairs. However, when recurring issues are not addressed properly, it undermines trust in body shop services, leading to dissatisfaction and potential reputational damage for the shop. Identifying and understanding these challenges is crucial for improving processes and ensuring customer satisfaction within the auto body restoration industry.

By examining case studies of PDR (Pre-Delivery Inspection) limitations, we’ve uncovered valuable insights into common challenges that can negatively affect vehicle quality and customer satisfaction. Recognizing these issues is crucial for improving inspection systems and fostering trust in the automotive industry. Understanding real-world scenarios allows us to implement more robust solutions, ensuring better vehicle condition transparency and enhanced client experiences.